Case History

Via Circonvallazione Est, 1, 24040 - Stezzano - BG

+39 035 4151111

www.schneider-electric.com

Schneider Electric Spa

Mechanical industry, Electrical & Electronics

Steelmaking, heavy industry and shipbuilding machinery in the 19th century. Electricity and automation management in the 20th century. In its 170-year history, Schneider Electric has faced many challenges and made important strategic choices to become an industry leader.

Schneider Electric offers products, systems, solutions, and services to make power safe, reliable, efficient, and productive at all levels, from the complete plant to the individual outlet.

Schneider Electric

Schneider Electric's numbers in the world

A French giant of international standing, it has factories and distribution hubs in more than 100 countries around the world, with more than 170 years of history and a strong vocation. Over the years, the company has evolved and is now a global specialist in integrated energy management and automation solutions.

BILLIONS EUROS TURNOVER IN 2016

% TURNOVER IN EMERGING COUNTRIES

THOUSAND EMPLOYEES

AND MORE COUNTRIES

Plants in Italy

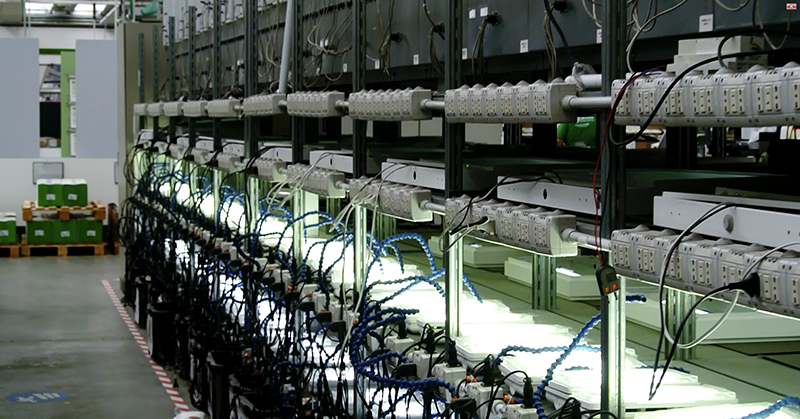

Warehouse Logistics

NUMBERS AND PLANTS IN ITALY

- Turnover: €621 million (in 2015)

- 1 single customer service center for all administrative and technical needs liv.1 and 2

- 1 integrated logistics center

- 160,000 people

- 8 business areas a widespread presence throughout the territory

- 3040 Employees (in 2015)

- 6 industrial sites including 5 global competence centers