Case History

Via delle Azalee, 19 - Buccinasco (MI)

Telephone: +39 02 335051

www.coimgroup.com

COIM

Chemical, Pharmaceutical & Medical

Since 1962, COIM has specialized in the production of polyesters, polyols, polyurethanes and special resins for the manufacture of composite materials and coatings. A rapidly expanding multinational corporation and a leader in the chemical industry worldwide, with plants in Europe, Asia and America.

Logistics Experience

Logistics Experience - C.O.I.M.

Interview with Massimo Tonani and Paolo D'Adda

The numbers of COIM

Global leader of the chemical industry

PLANTS IN 3 CONTINENTS

TOTAL FACILITIES

AND MORE PEOPLE

LOGISTICS CENTRE

A key element of the COIM Group's growth is its constant drive toward progress and innovation.

The company chose to rely on Replica Sistemi - Zucchetti for a yard management efficiency project at its Offanengo (CR) site.

The Offanengo production center has special characteristics:

- under Seveso III law for the management of hazardous substances

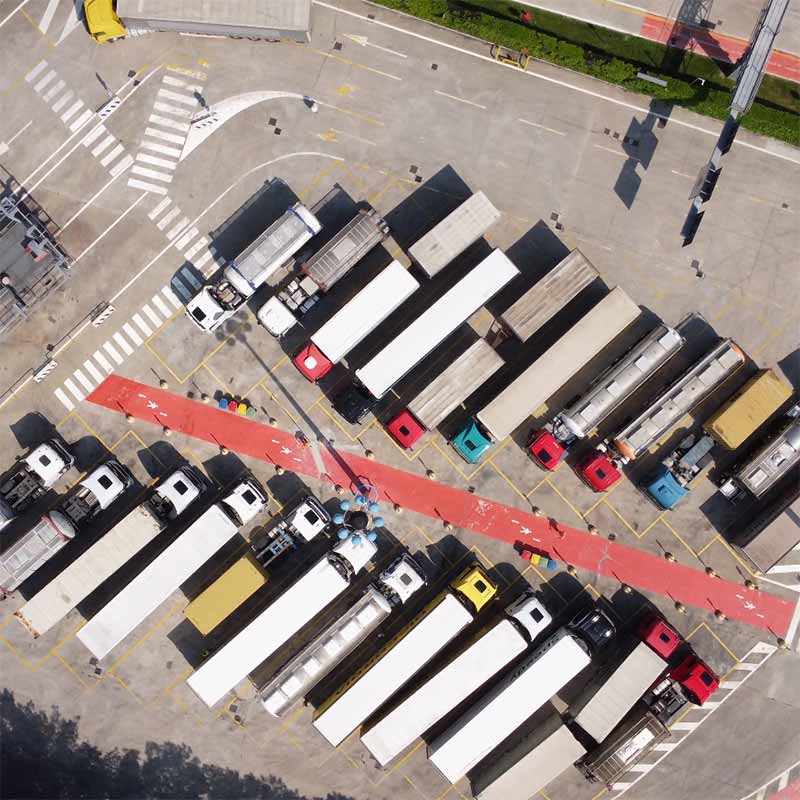

- surface area: over 28,000 square meters

- loading/unloading areas: 43

- flow in the yard: approx. 110 vehicles/day

NEEDS

YARD MANAGEMENT BEFORE EASYARD

Prior to the implementation of EasYard, the management of incoming vehicles for loading/unloading activities was completely manual and there was no scheduling of arrivals.

The driver would wait in the outside parking lot to register with the concierge by filling out a paper document.

The concierge communicated with the warehouse by telephone and with the driver by microphone with loudspeaker.

The weigh-in was recorded manually, and the assigned gate was indicated by a paper map.

Waiting times were long and queues were often created at the gatehouse. Drivers arriving during nighttime hours had to wait in the parking lot until staff arrived.

It was also difficult to monitor the presence and status of vehicles inside the plant.

THE CRISIS OF TRUCK DRIVERS IN EUROPE

Driver shortage is a growing problem in the trucking market: 600,000 vacancies today, 2 million expected by 2026.

Chemical industry associations are promoting investments to streamline logistics operations and increase driver comfort. The EasYard project is part of COIM's contribution.

GOALS

The development of the project was focused mainly in two areas:

- yard management;

- management of loading/unloading operations.

The goals of the project were:

- improvement of working conditions of company staff and drivers;

- immediate and differentiated communication to all internal and external stakeholders;

- real time tracking & tracing of physical flows of goods and people in the yard;

- loading/unloading process efficiency and consequent cost reduction;

- increased safety and security of the yard.

>

>

Download file

Download file